Not all the products we design have a long or extensive development process; Twisted’s new engine cover for example. A local-to-global success story, Twisted Automotive have been modifying and customising the iconic Land Rover Defender for over 20 years. You can find out more about their story here www.twistedautomotive.com. In their obsessive quest to make Defender the best it can be they consider again and again every single component, even the ones that are never seen.

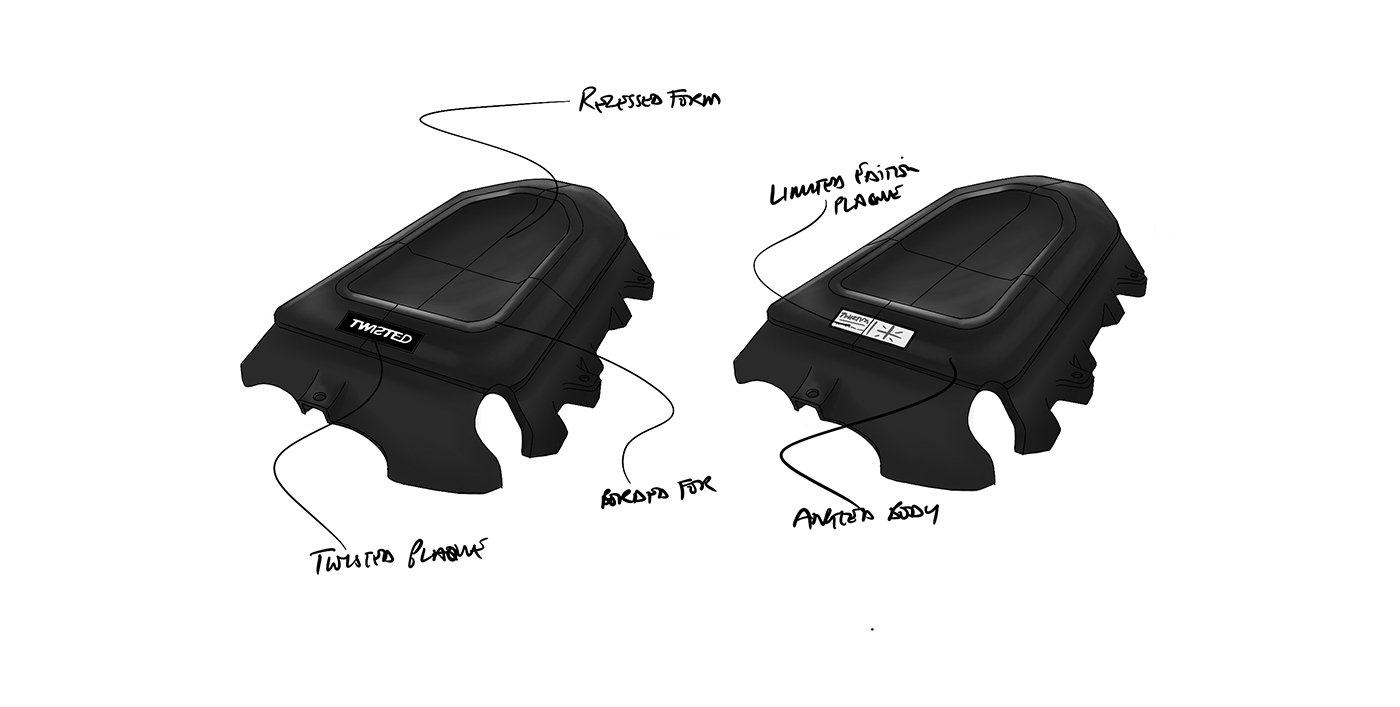

So, when they were developing their latest engine package – the Chevrolet LT1 V8 mated to an 8-speed automatic gearbox – the standard, off-the-shelf, engine cover was never going to be good enough to satisfy their attention to detail. At this point, they turned to us to help create a new Twisted engine cover more in line with their understated aesthetic.

The original, off-the-shelf Chevrolet LT1 V8 engine cover

Because their manufacturing volumes will be very low, injection moulding was far too expensive, so another solution was required. Vacuum casting, vacuum forming, and 3D printing were all investigated as potential manufacturing processes. However, after helping them to weigh up the opportunities and drawbacks through a feasibility research matrix, we eventually settled on CNC machining a solid block of FRP (Fire Retardant Polycarbonate) as the best solution.

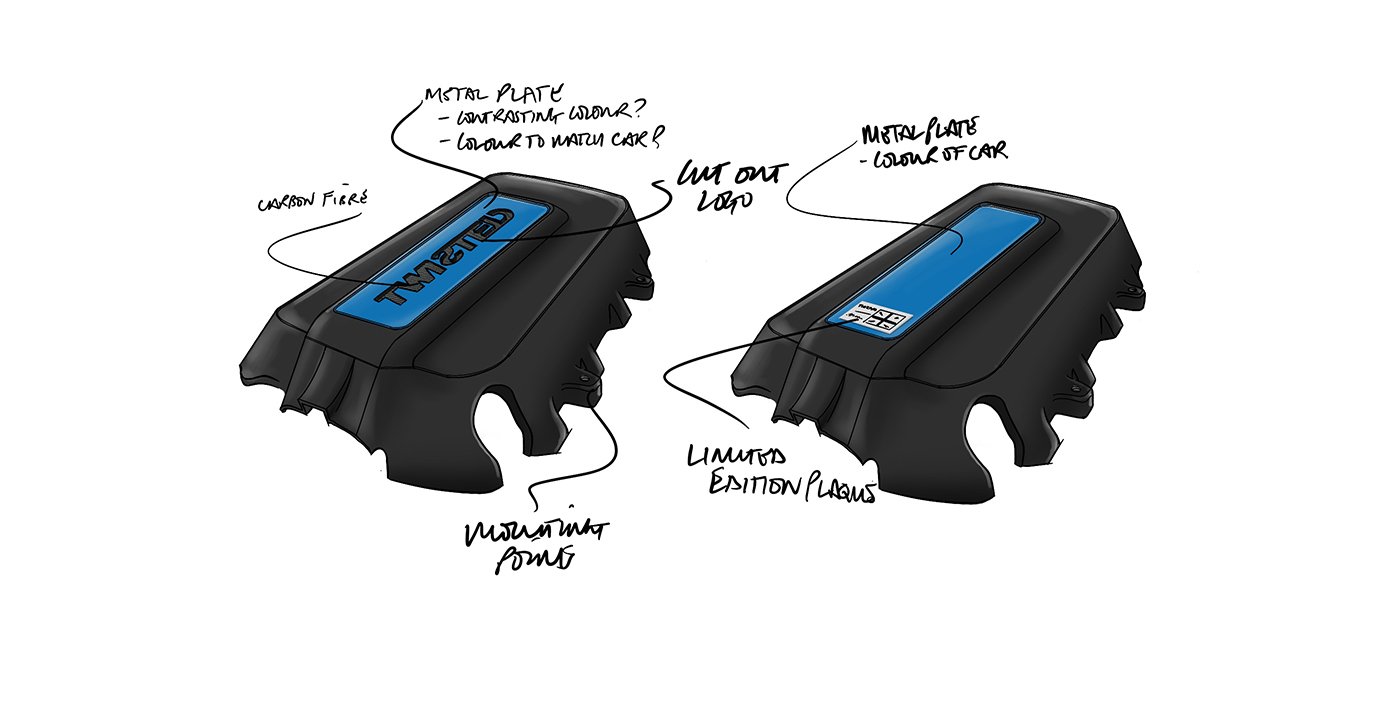

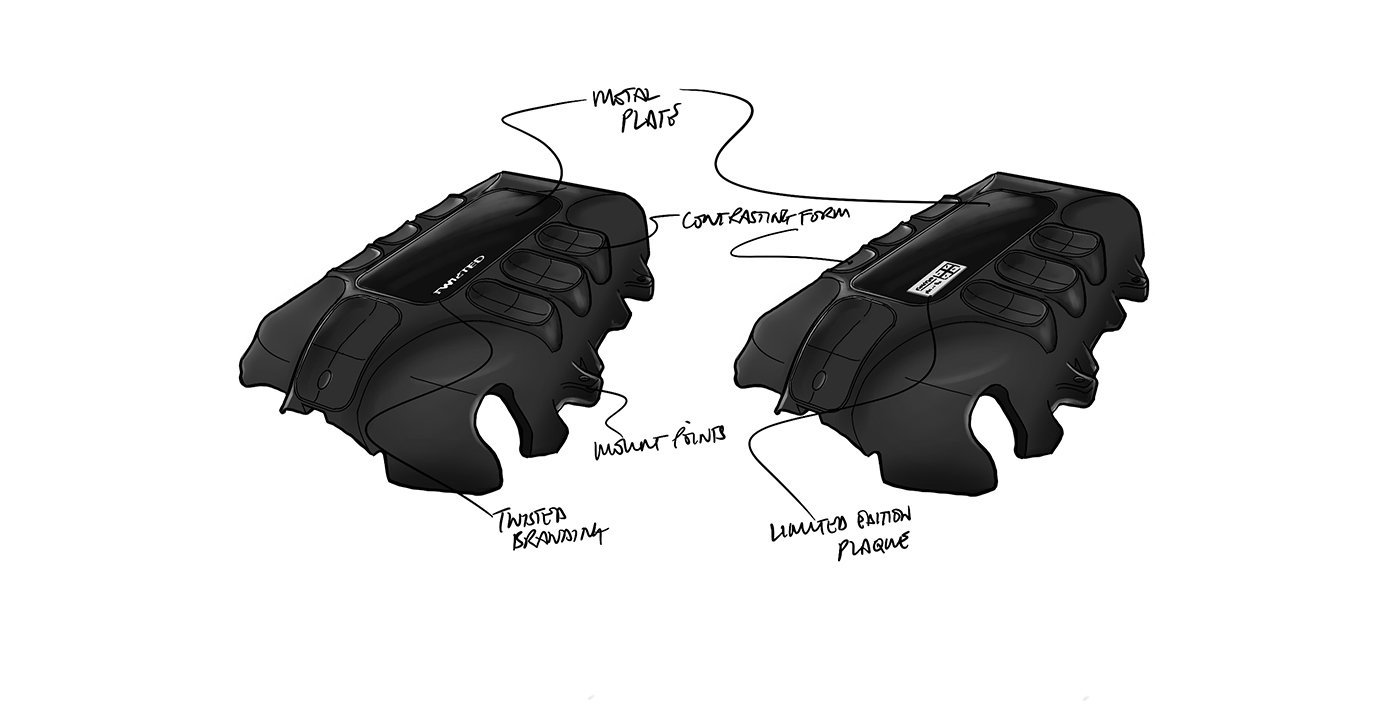

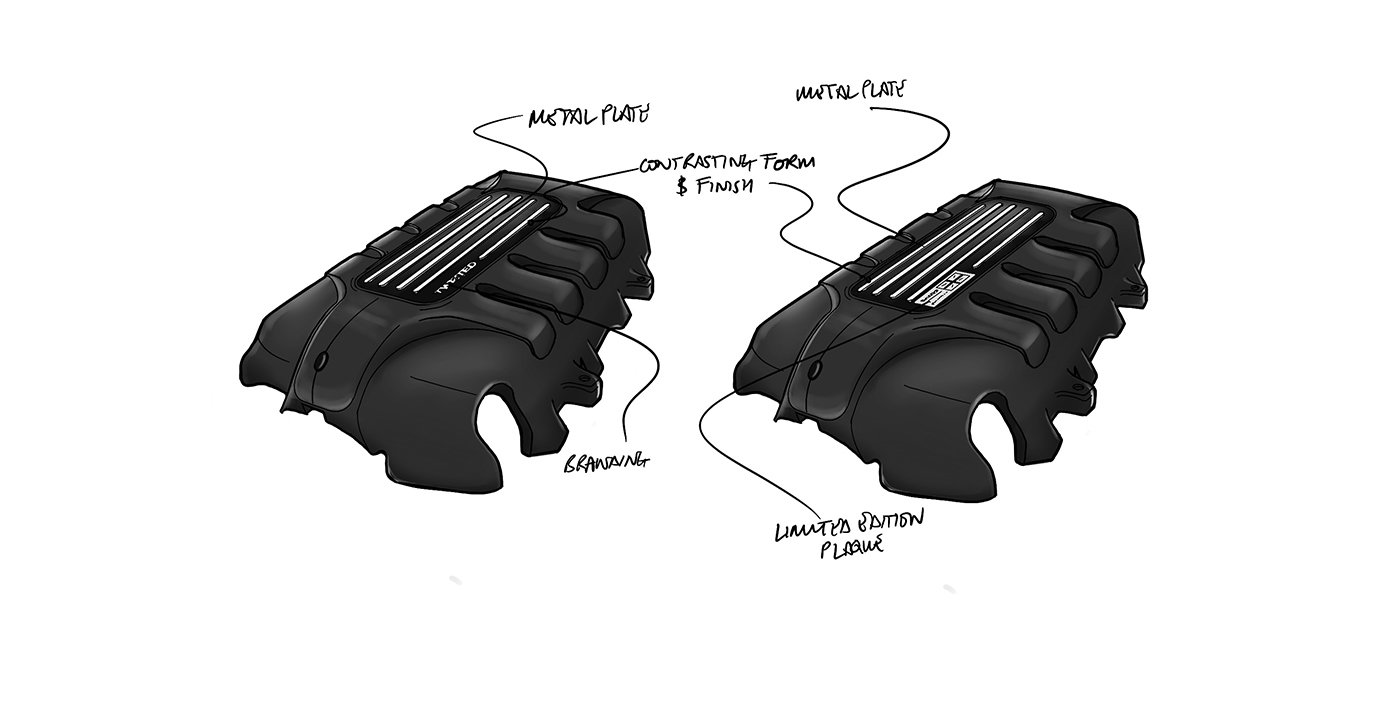

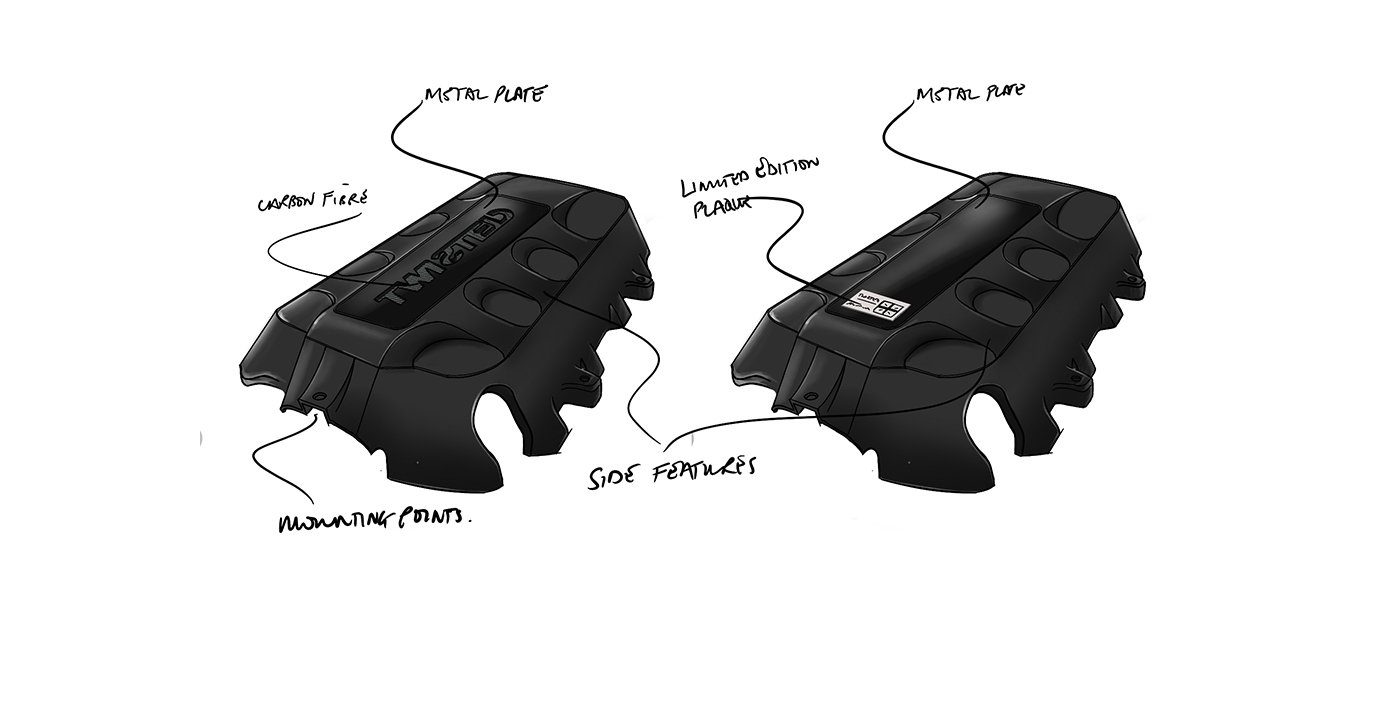

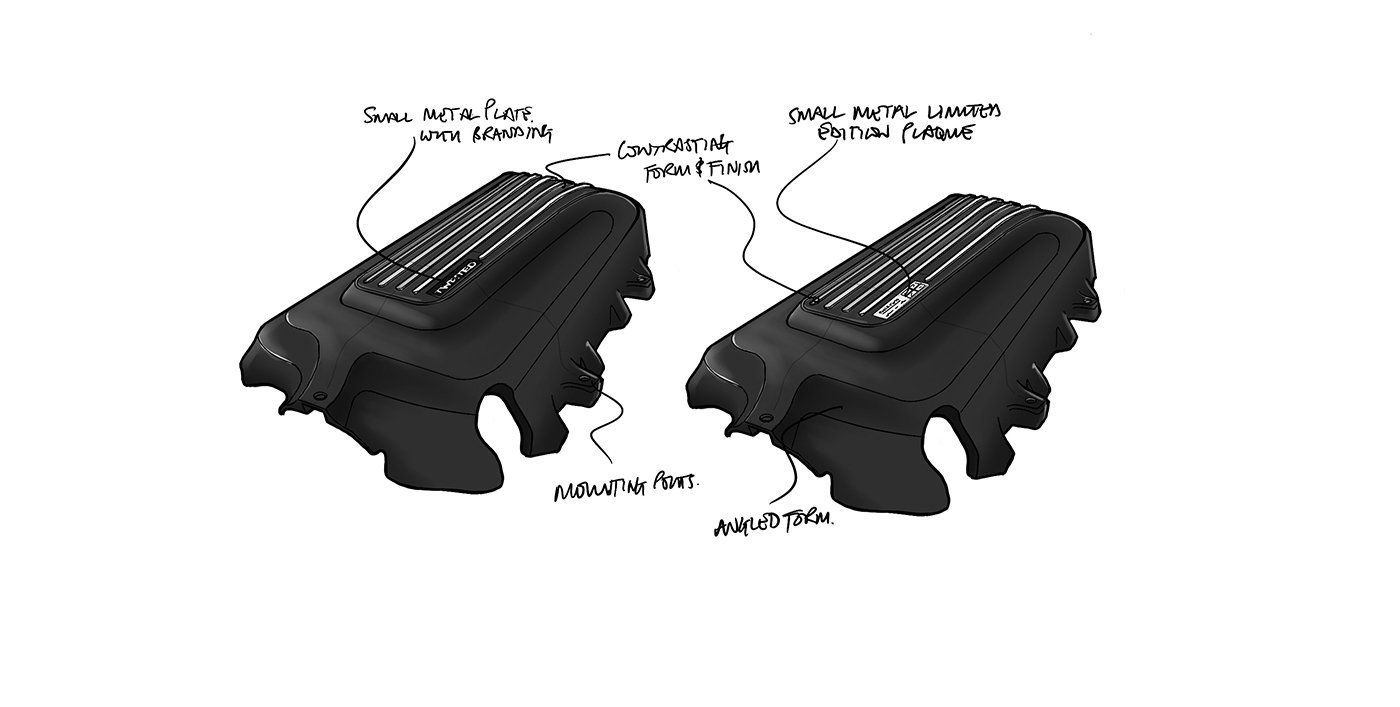

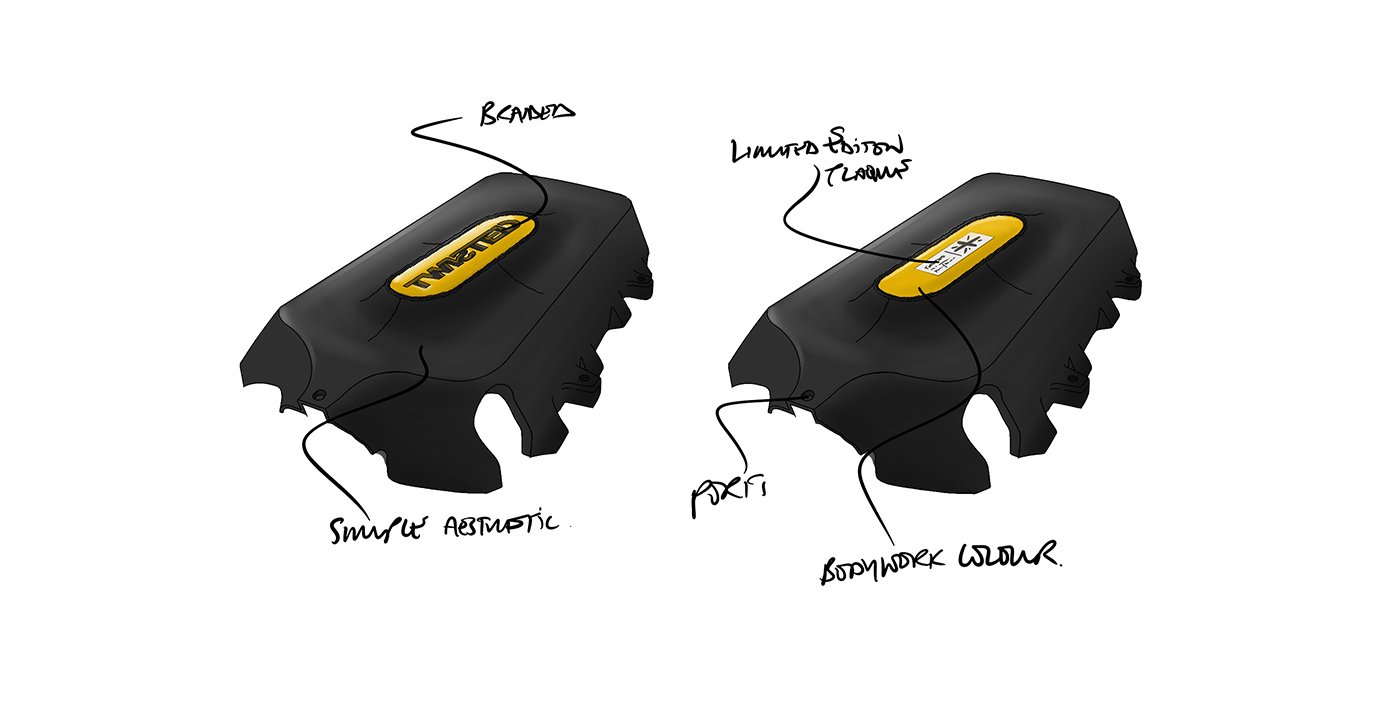

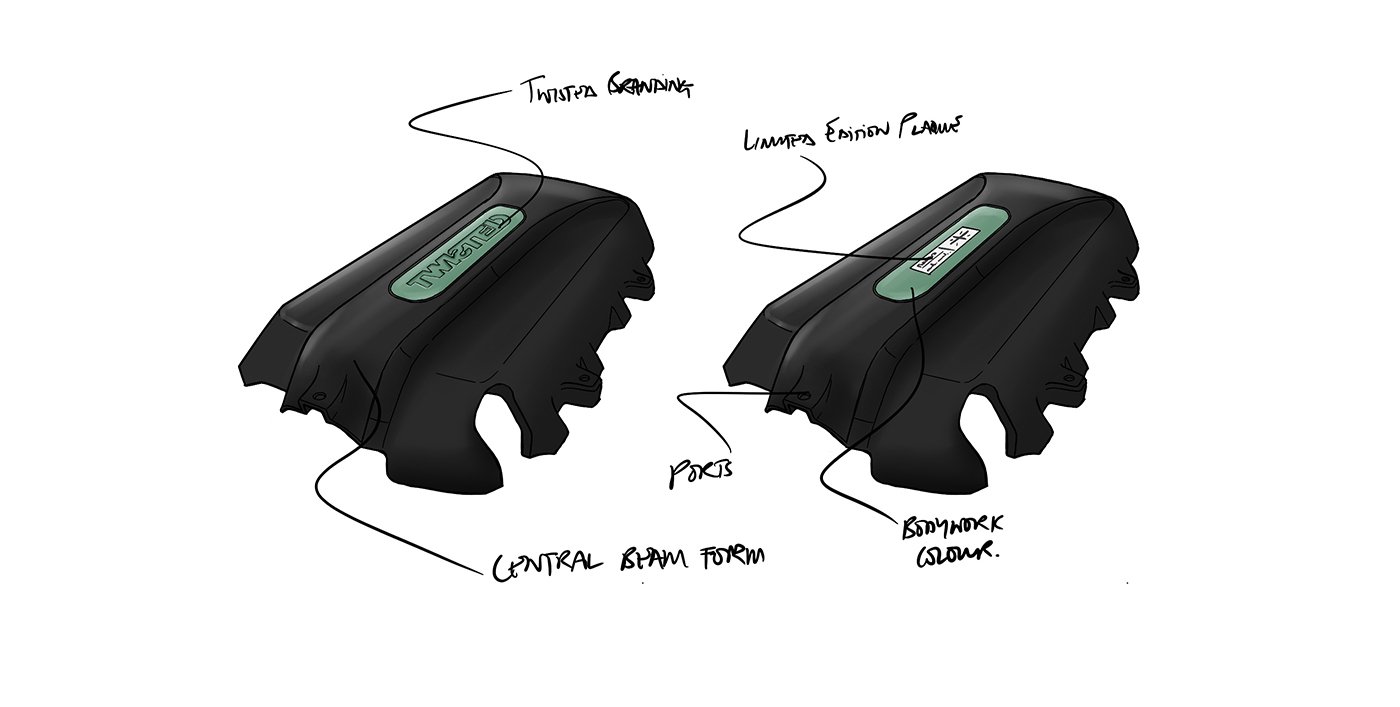

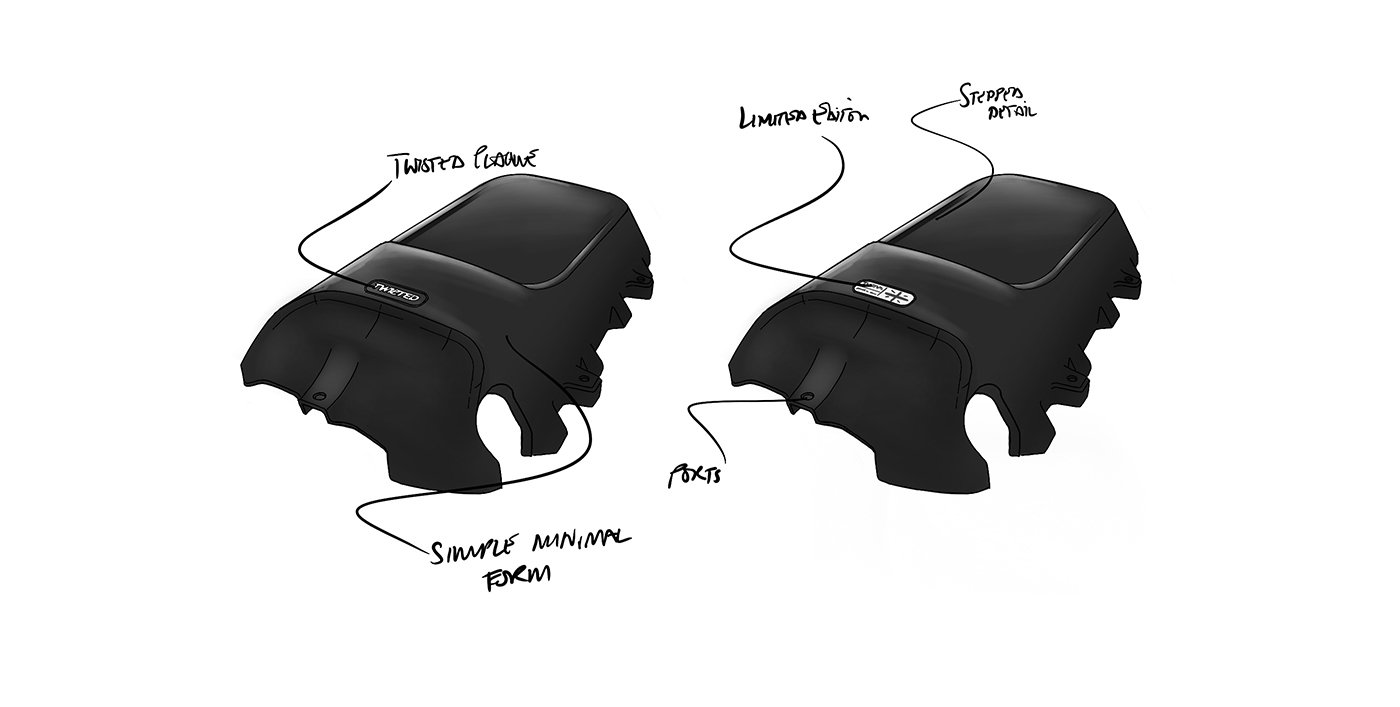

The design process started with meticulous and extremely precise measuring, reverse engineering the existing engine cover to create a new CAD model. Sketches were then made, exploring aesthetics and the size and positioning of the Twisted identity, to reflect Twisted’s brand values.

Sharing these ideas with the client team, we soon honed-down the concepts to a selected design and developed the CAD model to meet the new specification; before 3D printing a 1:1 prototype using our FDM printers. This gave both teams the chance to see and feel the new engine cover, full-size, for the first time.

New specification 3D printed 1:1 prototype

We then went through many small yet important iterations until we had a fit that was absolutely perfect, while ensuring it had enough clearance from all other components in and around the engine bay.

The first-off, production quality, CNC machined engine cover

The final step was to produce the first-off, production quality, CNC machined engine cover for real-world testing and final approval. The results were brilliant and, with the first production run now complete, there are now customer cars on the road with the new engine covers custom painted to match the cars they are fitted to.

The goal here wasn't just to design a new engine cover that looked good and was fit-for-purpose (safe, reliable, and meet current automotive regulations). It was also to guide and assist Twisted with its manufacture and supply chain management; providing them with all the necessary documentation and systems, so they can call-off new covers as and when they need them.

A very happy client and an exciting project for us, particularly because we facilitated Twisted’s aspirations for making the best, better.

““Twisted have bold ambitions to become the global leader in customising Land Rover Defenders. Whilst we have some capacity in-house we needed to work with an organisation who can push the boundaries, apply breathtaking innovation and practical engineering experience. Pd-m are cognitive thought leaders and practical designers who have the unique ability to convert concepts into commercially viable solutions.””